Glass surface stress measuremment

Ensuring Glass Safety in Modern Construction and Architecture

Take a walk around the city today, and it’s easy to notice one thing: glass is everywhere. High-rise buildings, shopping malls, offices, even coffee shops are competing to use glass for light and open space. It looks sleek and modern, but few people think about this question: are those glass panels really safe? Could they suddenly shatter? In fact, there have already been numerous cases where falling glass left both developers and residents shocked.

Why is glass more fragile than we think?

Glass is not like steel or wood. It is brittle and sensitive. Just a small crack or an uneven internal stress can lead to failure. In the industry, this is called surface stress of glass. If the stress is unevenly distributed some areas under tension, some under compression the glass can spontaneously explode even without any impact. You’ve probably heard of balcony glass or windows shattering out of nowhere. That is exactly the result of uncontrolled stress. Especially with tempered glass, the heat-strengthening process generates internal stresses.

A story from a real project

A friend of mine, a supervising engineer, once told me about an office building that had glass panels on its façade shatter just a few months after opening. Fortunately, it happened late at night when no one was passing underneath. Upon inspection, the cause turned out to be improper stress testing. The contractor blamed the glass supplier, and the supplier blamed the installation. In the end, nobody had actually measured the stress from the beginning.

This isn’t rare. Many residential projects, in the rush to meet deadlines and cut costs, skip the step of stress testing with proper equipment. The consequences… whoever is unlucky enough bears them.

The role of glass stress in safety

Architectural glass is not just about aesthetics. It is a protective barrier. Glass railings keep balconies safe, glass partitions withstand storms, curtain walls shield thousands of square meters of surface area. For a piece of glass to be up to standard, it must withstand loads, impacts, and harsh weather. But all of this means nothing if its internal stress is unstable. In a high-rise building with thousands of glass panels, even one unexpected shattering can pose a serious risk to people walking below.

Abroad is no exception

It’s not just in Vietnam. Even in Singapore, Hong Kong, or the US, there are occasional reports of skyscraper glass shattering. The difference is that they have strict inspection procedures. Stress testing is performed at the factory, and random checks are also carried out after installation.

Here, however, this step is still not given enough attention. Surface stress meters for glass are already available on the market brands like Jinanod or Strainoptics but they mostly appear in large-scale projects or among professional firms. The majority of mid-sized and small projects still rely mainly on experience.

Practical applications of glass stress measurement

Measuring tools are no longer bulky. There are benchtop models for laboratory use, such as the FSM-6000LE, commonly used in factories to test batches of glass. These units provide very clear readings, showing exactly which areas are under compression and which are under tension, allowing engineers to adjust the tempering process immediately.

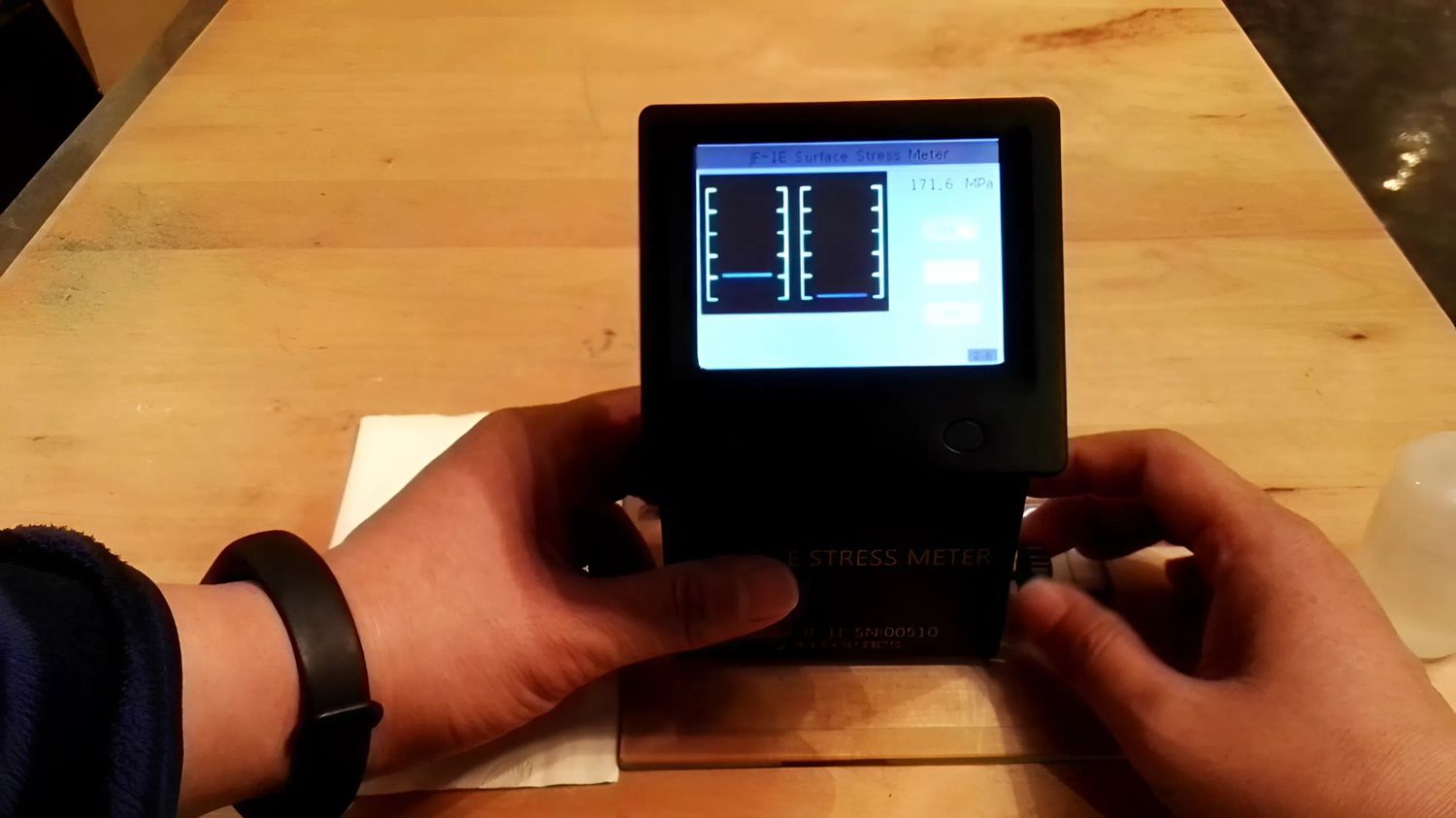

On the other hand, at construction sites, nobody brings along heavy systems. In such cases, engineers prefer compact tools like the Strainoptics GASP. This handheld device can be placed directly on the glass surface to provide instant results, making it ideal for quick checks during installation.

Lessons from those who invest and those who save

Personally, I think the trend of using glass in Vietnamese architecture will continue to rise. Glass houses, glass apartments, glass offices everyone wants brightness and a modern look. But alongside that, stress control must become a mandatory practice.

In fact, I’ve seen factories that invested in full Jinanod systems to control quality right from the input stage, and those factories rarely face glass-related incidents. On the contrary, companies that cut corners here are always “putting out fires” after problems occur.

Conclusion

Glass makes our cities brighter and more beautiful, but it only matters when it is safe. And safety cannot rely on luck; it must start with controlling surface stress.

Hopefully, in the coming years, glass stress testing will no longer be considered a luxury but will become a mandatory standard in every project.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-