Quick and technical ways to check capacitors

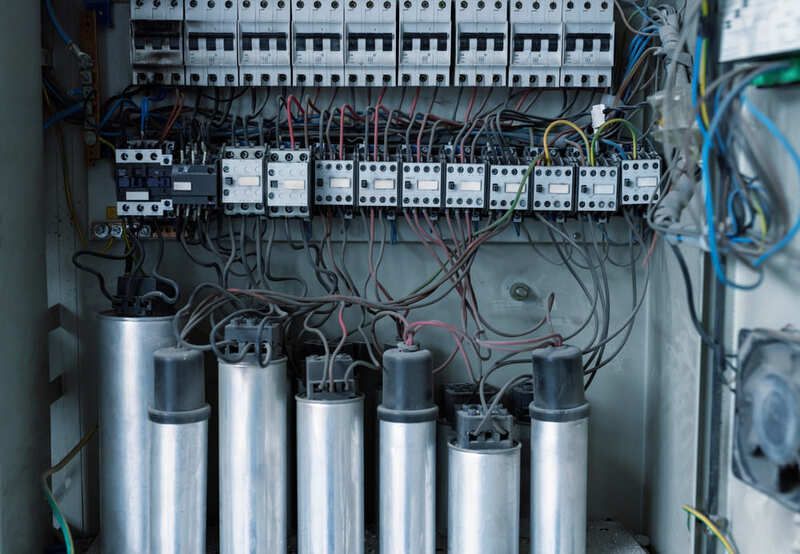

For the capacitor bank to operate stably and effectively, periodic inspection and maintenance are necessary. This helps to detect potential problems early and ensures the system always operates smoothly. In this article, EMIN will share with you simple and easy-to-implement ways to check capacitor banks.

Contents

Some common errors in capacitors and how to handle them

During operation, the capacitor bank may encounter some of the following common problems:

Relay self-reset: The capacitor bank relay may suddenly return to the factory settings (reset), causing the capacitor to not receive the on/off command or receive but not execute. When encountering this error, you need to check the entire operation of the system and reset the relay parameters.

No cosφ value displayed: This error is often caused by incorrect connection of the current signal or incorrect measurement of the voltage supplied to the relay, leading to no power factor (cosφ) displayed. The solution is to recheck the wiring diagram, ensure accuracy, and review the on/off operation of the relay.

Overvoltage relay: When overvoltage is detected, the relay will automatically cut off the power to protect the capacitor bank and reset the set parameters. If not reset, the capacitor bank will operate incorrectly. If overvoltage occurs frequently, it can damage the relay.

Relay input current is too small: When the current input to the relay is too low, the capacitor bank control process will be ineffective. The cause may be due to incorrect selection of the current transformer ratio or large angle error. To handle this, you need to replace the current transformer with a more suitable one for the system.

Swollen and exploded capacitors: Usually due to poor capacitor quality, incorrect connection, poor electrical contact or unsuitable installation environment. It is necessary to clearly identify the cause for handling, possibly re-connecting correctly or replacing with a new capacitor of better quality.

3 common ways to check capacitors

When using an electrical system with integrated capacitors, periodic inspection is essential to ensure stable operation of the capacitors, timely detection and replacement of damaged or degraded capacitors. Currently, there are 3 commonly used methods of checking capacitors, including: measuring with a capacitance meter (the most accurate method), a multimeter and a clamp meter.

Check capacitor with capacitance meter

Capacitance is the most important parameter reflecting the operating status of the capacitor. Therefore, using a capacitance meter is a method to check whether the capacitor is alive or dead with high accuracy. Based on the measured capacitance value, you can know whether the capacitor is still working well or needs to be replaced. Note: Before measuring, make sure the capacitor is unloaded and fully discharged.

When measuring each phase, you need to short-circuit the remaining two phases, then perform the measurement between the phase to be tested and the short-circuited phase. The result obtained divided by two will be the capacitance of that phase. Do this in turn with the remaining phases.

Refer to some standard capacitance values from BTB Electric dry capacitors:

Capacitor 5kVAr – 240V: C = 3×97μF

Capacitor 10kVAr – 250V: C = 3×170μF

Capacitor 15kVAr – 415V: C = 3×93μF

Capacitor 20kVAr – 440V: C = 3×110μF

Capacitor 25kVAr – 480V: C = 3×115μF

Capacitor 30kVAr – 525V: C = 3×115μF

Check capacitor with multimeter

The method of checking capacitor compensation with a multimeter is quite similar to using a capacitance meter. With AC capacitors, you need to select AC voltage measurement mode; with DC capacitors, switch to DC voltage measurement mode. Then, turn the knob to capacitance measurement mode and measure as usual.

Some current multimeter models are equipped with an additional REL (Relative) mode, which helps eliminate the influence of the capacitance of the measuring wire, especially useful when testing capacitors with small capacitance. To activate, you just need to open the two ends of the measuring wire, press the REL button, and then measure as usual.

Check capacitor with clamp meter

In addition to the direct capacitance measurement method, you can also check the compensation capacitor by measuring the current running through the capacitor when the system is operating with a clamp meter. This is an indirect measurement method, applied when the capacitor is operating under a stable voltage, reaching the rated value.

By measuring and comparing the current through the capacitor at different times, you can easily detect whether the capacitor is operating at the correct capacity or not, thereby providing a solution if necessary.

Notes on current when checking capacitors

When measuring the capacitor, pay special attention to the remaining charge on the capacitor. After disconnecting the capacitor from the grid, the terminals may still retain residual charge, so it is necessary to wait for a period of time for the capacitor to discharge itself. In case of urgent testing, you can discharge quickly by connecting a current-limiting resistor to the capacitor terminals, allowing the charge to discharge through the resistor and then connecting it to the ground, avoiding short circuit or damage to the capacitor.

In addition, when checking 3-phase capacitors, it is necessary to ensure that the current through the 3 phases is balanced and close to the rated value printed on the capacitor label. After a long time of use, the current through the capacitor may decrease slightly, which is a sign that the capacitor has degraded and needs to be closely monitored.

Refer to some standard current values when measuring on BTB Electric dry capacitors:

5kVAr capacitor – 240V: I = 12A

10kVAr capacitor – 250V: I = 23A

15kVAr capacitor – 415V: I = 21A

20kVAr capacitor – 440V: I = 26A

25kVAr capacitor – 480V: I = 30A

30kVAr capacitor – 525V: I = 33A

Conclude:

EMIN has just shared with you methods of checking compensation capacitors with specialized equipment, along with common errors and how to handle when compensation capacitors have problems. Hopefully this information will help you more easily check and operate the compensation capacitor system effectively and safely. Don't forget to visit the EMIN website to learn more about documents, equipment and products related to dry compensation capacitors.